I am well pleased with this unit, no more freezing in the garage for me. I too run the unit on medium but money well spent.

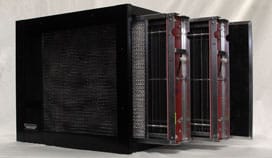

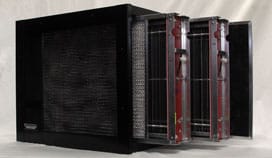

The old English humidor cabinet arrived without any damage and is absolutely beautiful if you are considering this humidor cabinet for your tobacco products do not hesitate to buy. It’s even more beautiful in person!

Seems look expensive for what they are, but they’re good rubber

Water chamber seal is not adequate, and there are no fittings as in the pick for the actual mist tubbing.

It working well at this point.